Description

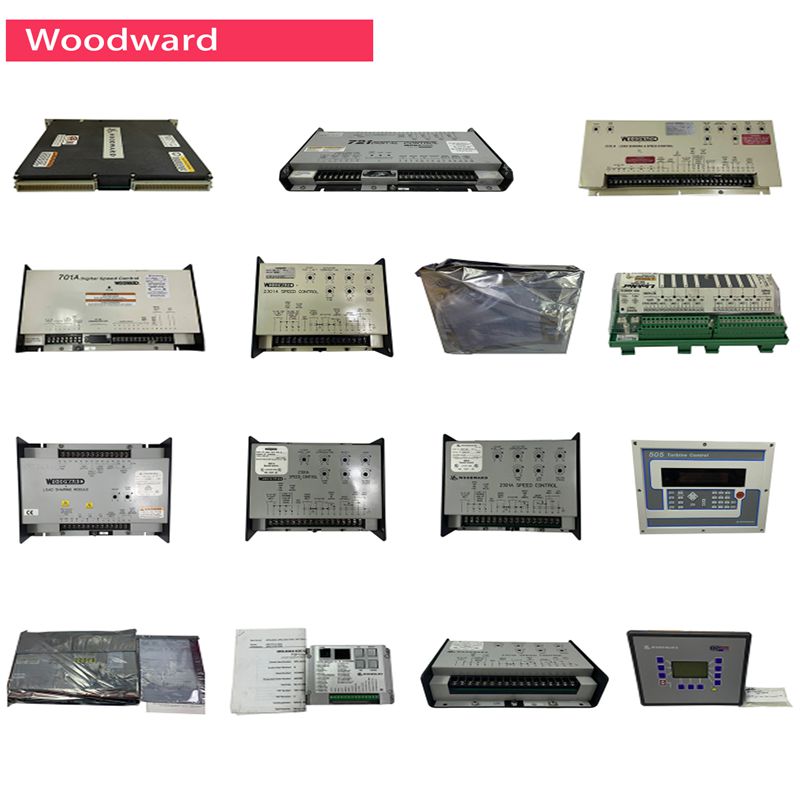

Woodward TG13 8516-043 Servo Valve

Product Dimensions:

Woodward is a global leader in the design and manufacture of high-performance control solutions. Their Servo Valves are critical components in hydraulic systems where precise control of flow or pressure is required.

Here is a detailed breakdown of Woodward Servo Valves.

1. Product Description

Woodward servo valves are electro-hydraulic devices that serve as the interface between electrical control signals and hydraulic power. They convert low-power electrical inputs into high-precision hydraulic outputs (flow or pressure).

Most Woodward models utilize a Nozzle-Flapper or Deflector Jet pilot stage to drive a second-stage sliding spool. These valves are renowned for their ruggedness, high frequency response, and “dirt tolerance” in demanding environments.

2. Technical Parameters

While specific parameters vary by series (e.g., HR Textron heritage models or the 445 series), general specifications typically include:

| Parameter | Typical Range / Value |

| Rated Flow | From 1 GPM to 60+ GPM (at 1000 psi drop) |

| Operating Pressure | Up to 5,000 psi (350 bar) |

| Input Signal | ±10mA, ±50mA, or 4-20mA (Digital versions available) |

| Hysteresis | < 3% (Standard) / < 1% (High performance) |

| Frequency Response | Up to 100 Hz – 200 Hz (90° phase shift) |

| Fluid Compatibility | Mineral oils, Jet fuel, or Skydrol (Phosphate Ester) |

| Null Shift | < 2% over temperature/pressure changes |

3. Product Advantages

-

High Dynamic Response: Capable of extremely fast reactions to control signals, essential for flight controls and turbine bypass systems.

-

Contamination Resistance: Woodward’s Deflector Jet technology is designed to handle “dirty” oil better than traditional nozzle-flapper designs, reducing the risk of clogging.

-

Precision and Accuracy: Exceptional linearity and low hysteresis ensure that the hydraulic output matches the electrical input almost perfectly.

-

Durability: Engineered for harsh environments, including high vibration, extreme temperatures, and corrosive atmospheres.

-

Fail-Safe Options: Many models include mechanical or electrical “null centering” to ensure the system returns to a safe state if power is lost.

4. Key Considerations (Precautions)

-

Fluid Cleanliness: Despite their “dirt-tolerant” design, hydraulic fluid must be filtered to at least ISO 4406 16/14/11 or better to prevent premature wear and sticking.

-

Seal Compatibility: Ensure the seal material (Buna, Viton, or EPR) matches the type of hydraulic fluid being used (e.g., Skydrol requires special seals).

-

Bleeding Air: Air trapped in the valve can cause instability or “chatter.” Always bleed the hydraulic system thoroughly during installation.

-

Mounting Torque: Follow exact torque specifications when mounting the valve to the manifold to avoid warping the valve body.

5. Typical Applications

Woodward servo valves are primarily used in high-stakes industries:

-

Aerospace: Flight control surfaces (elevators, rudders), engine fuel metering, and landing gear systems.

-

Power Generation: Controlling steam and gas turbine fuel valves, as well as Inlet Guide Vane (IGV) actuators.

-

Industrial Machinery: High-speed plastic injection molding, material testing rigs, and large-scale hydraulic presses.

-

Oil & Gas: Subsea control modules and blowout preventer (BOP) systems.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| WOODWARD | 8552-674 |

| WOODWARD | 8552-558 |

| WOODWARD | 8440-2088 |

| WOODWARD | 5464-835 |

| WOODWARD | 5463-785 |

| WOODWARD | 5439-929 |

| WOODWARD | 8273-1011 |

| WOODWARD | 9907-147 |

| WOODWARD | 8200-226 |

| WOODWARD | 9907-162 |

| WOODWARD | 5453-276 |

| WOODWARD | 5501-470 |

| WOODWARD | 9905-797 |

| WOODWARD | 9907-005 |

| WOODWARD | 9907-252 |

| WOODWARD | 5466-316 |

| WOODWARD | 5466-348 |

| WOODWARD | 8440-1706 |

| WOODWARD | 9907-167 |

| WOODWARD | 5501-471 |

| WOODWARD | 1680-2004 |

| WOODWARD | 2301A 9907-018 |

| WOODWARD | 2301D |

| WOODWARD | 2301E 8273-1011 |

| WOODWARD | 5136-DN-PC |

| WOODWARD | 5136-PFB-104 |

| WOODWARD | 5136-PFB-ISA |

| WOODWARD | 5136-PFB-PCI |

| WOODWARD | 5136-PFB-VME |

| WOODWARD | 5136-RE2-PCI |