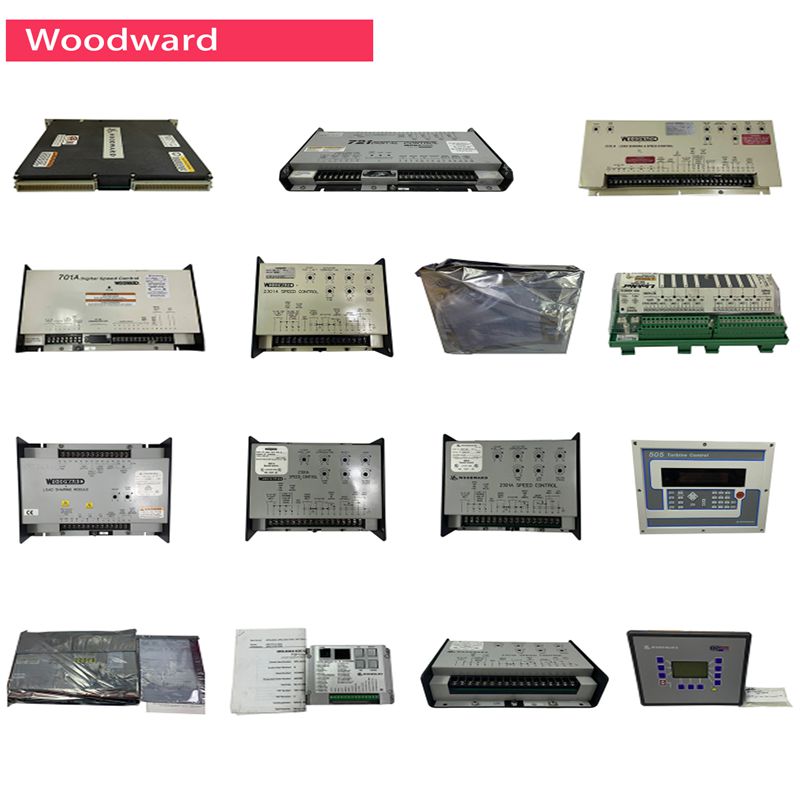

Description

Woodward DC10502-000-012 Fuel Injection System

Product Dimensions:

Woodward is a global leader in the design and manufacture of high-pressure fuel injection systems for large diesel, dual-fuel, and gas engines. Their systems are renowned for enhancing engine efficiency, reducing emissions, and ensuring long-term reliability in demanding environments.

1. Product Description

Woodward’s fuel injection portfolio covers a wide range of technologies, from traditional mechanical components to advanced Electronic Fuel Injection (EFI) and Common Rail Systems (CRS). These systems are engineered to provide precise control over fuel atomization and injection timing, which are critical for meeting modern environmental standards (like IMO Tier III or EPA Tier 4).

Key Product Categories:

-

Common Rail Systems: High-pressure pumps and injectors that maintain constant pressure for flexible injection timing.

-

Mechanical Fuel Injection: Traditional pumps, lines, and nozzles for legacy engine support and specific heavy-duty applications.

-

Dual-Fuel Systems: Specialized injectors capable of handling both liquid fuel (diesel) and gaseous fuel (LNG/Natural Gas).

-

Electronic Unit Injectors (EUI): Integrated units that combine the pump and nozzle, controlled electronically for optimized combustion.

2. Product Parameters (Typical Specifications)

While specifications vary by specific model (e.g., SOGAV, L’Orange series), general parameters include:

| Parameter | Range / Typical Value |

| Injection Pressure | Up to 2,500+ bar (for Common Rail) |

| Engine Power Range | 500 kW to 20,000+ kW |

| Fuel Types | MGO, MDO, HFO, Bio-fuels, LNG, Methanol |

| Control Interface | CAN bus, J1939, or Analog signals |

| Operating Temperature | -40°C to +120°C (Fuel dependent) |

| Voltage | 24V DC (Standard for electronic controls) |

3. Product Advantages

-

Extreme Precision: Woodward’s solenoid technology allows for multiple injection events (pilot, main, and post-injection), which significantly lowers noise and vibration.

-

Fuel Efficiency: Optimized spray patterns and high pressure ensure complete combustion, reducing fuel consumption.

-

Durability: Built with high-grade materials to resist wear from low-lubricity fuels and harsh maritime or industrial environments.

-

Emission Compliance: Facilitates the reduction of $NO_x$ and particulate matter (PM) without sacrificing engine performance.

-

Modularity: Systems can be tailored to specific engine architectures, whether it’s a small power gen-set or a massive marine engine.

4. Important Considerations & Maintenance

-

Fuel Quality: High-pressure systems are extremely sensitive to contaminants. Use of high-quality filtration (down to 2–5 microns) is mandatory to prevent injector clogging or pump seizure.

-

Lubricity: When using Ultra-Low Sulfur Diesel (ULSD), ensure the fuel meets the minimum lubricity requirements to prevent premature wear on moving parts.

-

Installation: Correct torque settings for high-pressure fuel lines are critical. Over-tightening can cause cracks, while under-tightening leads to dangerous high-pressure leaks.

-

Software Updates: For EFI systems, ensure the Engine Control Unit (ECU) is running the latest Woodward-verified firmware to optimize performance.

5. Product Applications

Woodward fuel injection systems are found in industries where “downtime” is not an option:

-

Marine: Main propulsion and auxiliary engines for tankers, cruise ships, and tugboats.

-

Power Generation: Backup power for data centers, hospitals, and prime power for remote microgrids.

-

Rail: High-horsepower locomotives for freight and passenger transport.

-

Oil & Gas: Powering pumps and compressors on offshore rigs and midstream stations.

-

Mining: Large-scale hauling trucks and heavy earth-moving equipment.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| WOODWARD | 8552-674 |

| WOODWARD | 8552-558 |

| WOODWARD | 8440-2088 |

| WOODWARD | 5464-835 |

| WOODWARD | 5463-785 |

| WOODWARD | 5439-929 |

| WOODWARD | 8273-1011 |

| WOODWARD | 9907-147 |

| WOODWARD | 8200-226 |

| WOODWARD | 9907-162 |

| WOODWARD | 5453-276 |

| WOODWARD | 5501-470 |

| WOODWARD | 9905-797 |

| WOODWARD | 9907-005 |

| WOODWARD | 9907-252 |

| WOODWARD | 5466-316 |

| WOODWARD | 5466-348 |

| WOODWARD | 8440-1706 |

| WOODWARD | 9907-167 |

| WOODWARD | 5501-471 |

| WOODWARD | 1680-2004 |

| WOODWARD | 2301A 9907-018 |

| WOODWARD | 2301D |

| WOODWARD | 2301E 8273-1011 |

| WOODWARD | 5136-DN-PC |

| WOODWARD | 5136-PFB-104 |

| WOODWARD | 5136-PFB-ISA |

| WOODWARD | 5136-PFB-PCI |

| WOODWARD | 5136-PFB-VME |

| WOODWARD | 5136-RE2-PCI |