Description

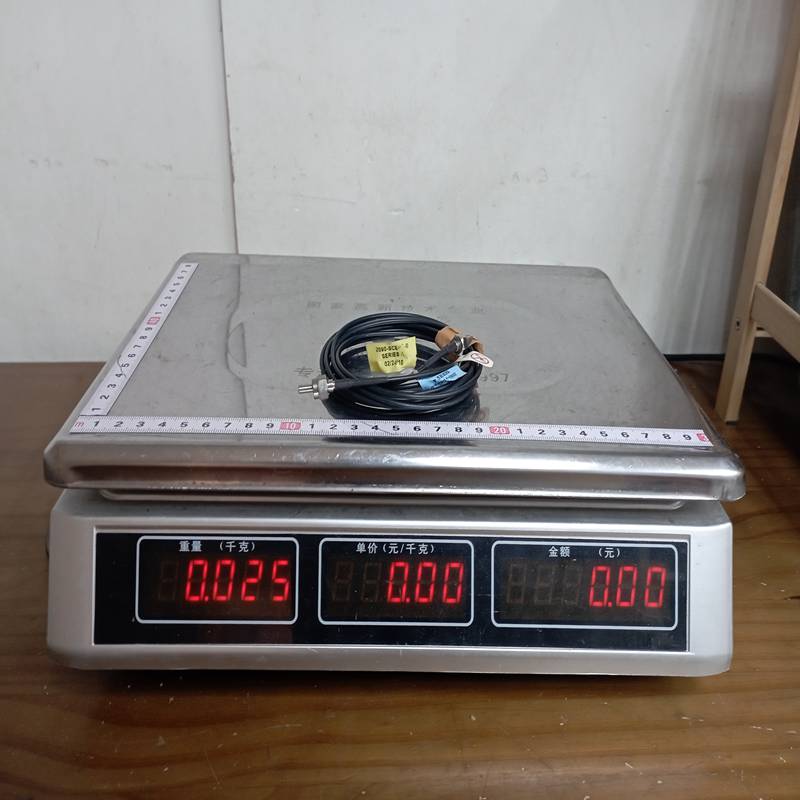

Allen-Bradley 2090-SCEP3-0 1G Plastic Fiber Optic Cable 1G

Product Dimensions:

The Allen-Bradley 2090-SCEP3-0 is a specialized feedback connector kit manufactured by Rockwell Automation. It is primarily used within the Kinetix servo drive ecosystem to facilitate reliable communication between the motor and the drive.

Here is a detailed breakdown of the product in English.

1. Product Overview

The 2090-SCEP3-0 is a low-profile, solder-type feedback connector kit. It is designed for use with high-performance servo systems where space is at a premium and a secure, permanent connection is required for encoder feedback signals.

2. Technical Specifications

| Feature | Specification |

| Manufacturer | Rockwell Automation / Allen-Bradley |

| Series | 2090 Motor Feedback Connector Kits |

| Type | Low-profile Feedback Connector |

| Connection Method | Solder-style contacts |

| Pin Count | Typically 20-pin (High density) |

| Compatibility | Kinetix 2000, 5500, 6000, and 7000 Servo Drives |

| Cable Diameter Support | Designed for standard Allen-Bradley feedback cables |

| Enclosure Rating | IP20 (intended for cabinet/drive-side use) |

3. Key Product Advantages

-

Space-Saving Design: The “low-profile” nature allows for tighter mounting of servo drives in a control cabinet, reducing the overall footprint of the system.

-

Signal Integrity: By using solder connections rather than crimp or screw terminals, it ensures a high-vibration resistant and low-resistance path for sensitive encoder data.

-

OEM Compatibility: Guaranteed to work with the Kinetix hardware ecosystem, eliminating the risk of pinout errors or physical mismatch.

-

Durability: Built with industrial-grade materials to withstand the electrical noise and thermal variations common in factory environments.

4. Important Considerations (Precautions)

-

Soldering Expertise Required: Since this is a solder-style kit, the quality of the connection depends on the technician’s skill. Poor soldering can lead to signal “noise” or intermittent faults.

-

Shielding: Ensure that the cable shield is properly terminated to the connector shell to prevent Electromagnetic Interference (EMI) from disrupting the feedback loop.

-

One-Time Use: Unlike screw terminals, solder connectors are difficult to rework. Double-check your pinout wiring diagram before applying heat.

-

Environment: Ensure the connector is used within its rated temperature and humidity specs; it is not intended for direct exposure to liquids or heavy dust without an additional enclosure.

5. Product Applications

This connector is typically found in high-precision motion control industries, including:

-

Packaging Machinery: Synchronizing multiple axes for high-speed wrapping or labeling.

-

Robotics: Connecting the feedback loops for articulated arms or pick-and-place delta robots.

-

CNC Machining: Providing the accurate positioning data required for metal cutting and milling.

-

Automated Assembly: Used in automotive or electronic assembly lines where Kinetix drives are the standard.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| AB | 1746-OB16 |

| AB | 1746-OB16E |

| AB | 1746-OB32 |

| AB | 1746-OB32E |

| AB | 1746-OB8 |

| AB | 1746-OBP16 |

| AB | 1746-OG16 |

| AB | 1746-OV16 |

| AB | 1746-OV32 |

| AB | 1746-OW16 |

| AB | 1746-OW16/C |

| AB | 1746-OW16/C/D |

| AB | 1746-OW4 |

| AB | 1746-OW8 |

| AB | 1746-OX8 |

| AB | 1746-P1 |

| AB | 1746-P2 |

| AB | 1746-P2/C |

| AB | 1746-P3 |

| AB | 1746-P4 |

| AB | 1746-P5 |

| AB | 1746-P6 |

| AB | 1746-P7 |

| AB | 1746SC-NI8U |

| AB | 1746SC-OAP8I |

| AB | 1747-ACN15 |

| AB | 1747-ACNR15 |

| AB | 1747-ACNR15/A |

| AB | 1747-ASB |

| AB | 1747-ASB/A |

| AB | 1747-ASB1747-L511 |

| AB | 1747-BA |

| AB | 1747-BSN |

| AB | 1747-BSN1771-IFE |

| AB | 1747-CP3/A |