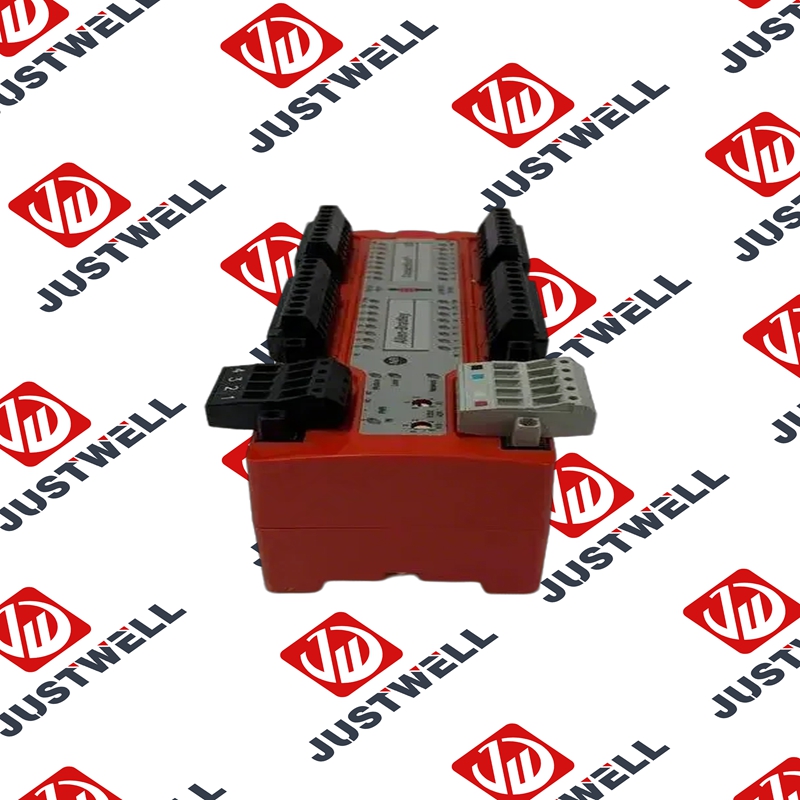

Description

2711P-T7C4A9 Allen‑Bradley Programmable controller

Product Dimensions:

Product Detailed Description

Allen-Bradley Programmable Logic Controllers (PLCs), produced by Rockwell Automation, are rugged, industrial-grade digital computers designed to automate electromechanical processes in manufacturing and other industrial environments. Invented in the late 1960s by Odo Josef Struger (often called the “father of the PLC”), Allen-Bradley introduced one of the first PLCs in 1970—the Bulletin 1774—to replace hardwired relay systems with programmable logic, reducing wiring complexity and improving flexibility. Today, Allen-Bradley PLCs have evolved into scalable Programmable Automation Controllers (PACs) that support multi-disciplined control, including discrete, process, motion, safety, and high-availability applications.

The product line includes families like:

- ControlLogix®: High-performance, modular systems for large-scale, complex applications requiring redundancy and extensive I/O.

- CompactLogix®: Compact, cost-effective controllers for medium-sized machines with integrated motion and safety.

- Micro800™ Series (e.g., Micro850®, Micro870®): Entry-level to mid-range for standalone machines, offering plug-in modules for expansion.

- MicroLogix™: Legacy small-scale controllers for basic automation (phasing out in favor of Micro800).

These controllers use a tag-based memory model for data organization and support programming in languages compliant with IEC 61131-3, such as ladder logic, structured text, function block diagrams, and sequential function charts. They integrate with the Connected Enterprise® architecture via EtherNet/IP, enabling real-time data sharing, remote monitoring, and cybersecurity features like centralized authentication.

Product Parameters

Allen-Bradley PLC parameters vary by family and model. Below is a summary table focusing on key specifications for popular families (e.g., ControlLogix 5570/5580, CompactLogix 5380, Micro850). Detailed specs are from Rockwell Automation documentation.

| Parameter | ControlLogix® 5580/5570 | CompactLogix® 5380 | Micro850® |

|---|---|---|---|

| Memory (User/Program) | 0.5–40 MB (user); up to 128 MB I/O memory | 0.5–10 MB (user); 1–4 MB I/O | 24 KB (program); 24 KB data |

| I/O Capacity | Up to 500 local/remote connections; expandable via chassis (4–17 slots) | Up to 256 I/O points; 31 local modules | Up to 132 I/O points; 8 plug-in modules |

| Processing Speed | 0.2–2 µs per K instruction; supports up to 256 motion axes | 0.2–1 µs per K instruction; up to 8 axes | 0.2 µs per K instruction |

| Communication Ports | USB 2.0; EtherNet/IP (integrated); supports ControlNet, DeviceNet, DH+, Modbus, HART | Dual EtherNet/IP; USB; serial (RS-232/485) | Ethernet; USB; serial (RS-232/485); expandable via plug-ins |

| Power Supply | 24V DC/120-240V AC; Energy Storage Module (ESM) for backup (capacitor-based, up to 12 days WallClockTime) | 24V DC; battery backup (up to 3 years) | 24V DC; battery backup (up to 3 years) |

| Operating Temperature | 0…60°C standard; -25…70°C extreme (XT models) | -20…60°C | -20…65°C |

| Dimensions (W x H x D) | 1.25″ x 6″ x 5.7″ (module); chassis up to 17 slots | 2″ x 4.9″ x 3.5″ (compact) | 3.15″ x 4.72″ x 3.03″ |

| Certifications | UL, CE, ATEX (Zone 2), SIL 2/3 safety | UL, CE, ATEX, SIL 2/3 | UL, CE, ATEX, SIL 2 |

| Programming Software | Studio 5000® Logix Designer® (v21+); supports up to 32 tasks, 1000 programs/task | Studio 5000® Logix Designer® | Connected Components Workbench® (CCW) |

Additional notes: Firmware revisions (e.g., v30+ for 5580) enable features like DDR backplane for faster EtherNet/IP (up to 41 ms updates). Connections limited to 500 (5570) or 1000 (5580). Environmental: Pollution Degree 2, altitude up to 2000 m, IP20/IP67 options for Armor models.

Product Advantages

Allen-Bradley PLCs stand out for their reliability, scalability, and integration in demanding environments. Key advantages include:

- Scalability and Flexibility: Modular design allows expansion from small machines (Micro800) to enterprise-wide systems (ControlLogix), supporting up to 500+ connections and multi-vendor integration via open protocols like EtherNet/IP and OPC UA.

- High Performance and Speed: Faster scan times (e.g., 0.2 µs/K) and integrated motion control reduce latency in high-axis applications, improving throughput by up to 20% compared to legacy systems.

- Enhanced Security and Safety: Features like electronic keying, source protection for Add-On Instructions, and SIL 2/3 certification minimize risks; centralized access control prevents unauthorized changes.

- Ease of Use and Productivity: Tag-based addressing simplifies programming; Studio 5000® offers simulation, diagnostics, and reusable Add-On Instructions, reducing development time by 30–50%. User-friendly interfaces support ladder logic mimicking relay diagrams for quick adoption.

- Reliability in Harsh Conditions: Extreme temperature models (-25…70°C) and IP67 Armor housings ensure uptime in dusty, wet, or hazardous locations; redundancy options achieve 99.999% availability.

- Cost-Effectiveness: Lower lifecycle costs through reduced wiring, remote diagnostics, and backward compatibility with legacy networks (e.g., DH-485), outperforming competitors in total ownership cost.

Precautions and Notes

To ensure safe and optimal operation, follow these guidelines from Rockwell Automation manuals:

- Installation and Handling: Install in enclosures with flame-retardant properties (5VA rating) per NEMA/IP standards; use ESD protection (grounding straps) during handling. Only qualified personnel should wire and configure. Avoid residential or UV-exposed areas.

- Power and Backup: Remove power before inserting/removing modules, SD cards, or batteries to prevent arcing in hazardous locations. Monitor battery/ESM levels (e.g., replace batteries every 3 years at 25°C); low battery triggers faults—do not exceed 30 days storage above 60°C.

- Firmware and Programming: Upgrade firmware only in Program mode using ControlFLASH®; interruptions revert to boot version, risking data loss. Test programs in simulation mode before deployment; enable “Major Fault on Connection Failure” for critical I/O.

- Hazardous Environments: For Class I Division 2/Zone 2, use certified enclosures (IP54+); no hot-swapping in explosive areas. Secure connections with screws/latches.

- Operational Warnings: Do not use Program mode as an E-stop; forces apply immediately—verify in Test mode. Limit USB use to temporary programming (<3m cable, no hubs). Dispose of lithium batteries per local regulations (AG-5.4).

- Maintenance: Schedule regular diagnostics via GSV/SSV instructions; monitor CPU usage (overhead time slice 10–90%) to avoid task overruns.

Failure to comply may void warranties or cause equipment damage.

Product Applications

Allen-Bradley PLCs are versatile for industrial automation across sectors, leveraging their robustness for real-time control and data analytics:

- Manufacturing and Assembly: Discrete control for conveyor systems, robotic welding, and automotive lines (e.g., CompactLogix for up to 256 I/O points in pick-and-place operations).

- Process Industries: Batch mixing, chemical dosing, and water treatment (ControlLogix with HART/Foundation Fieldbus for sensor integration in refineries).

- Material Handling: Sorting, packaging, and warehouse automation (Micro850 for standalone sorters with Ethernet connectivity).

- Energy and Utilities: Pump/valve control in power plants and oil/gas (extreme XT models for -25…70°C environments).

- Food & Beverage: Hygienic packaging and filling lines (IP67 Armor for washdown areas, SIL 3 safety).

- Motion and High-Availability: Coordinated drives in printing presses or redundant systems for 24/7 uptime in pharmaceuticals.

These applications benefit from integration with HMIs, drives, and cloud analytics for predictive maintenance, reducing downtime by up to 50%.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| AB | 1746-OB16 |

| AB | 1746-OB16E |

| AB | 1746-OB32 |

| AB | 1746-OB32E |

| AB | 1746-OB8 |

| AB | 1746-OBP16 |

| AB | 1746-OG16 |

| AB | 1746-OV16 |

| AB | 1746-OV32 |

| AB | 1746-OW16 |

| AB | 1746-OW16/C |

| AB | 1746-OW16/C/D |

| AB | 1746-OW4 |

| AB | 1746-OW8 |

| AB | 1746-OX8 |

| AB | 1746-P1 |

| AB | 1746-P2 |

| AB | 1746-P2/C |

| AB | 1746-P3 |

| AB | 1746-P4 |

| AB | 1746-P5 |

| AB | 1746-P6 |

| AB | 1746-P7 |

| AB | 1746SC-NI8U |

| AB | 1746SC-OAP8I |

| AB | 1747-ACN15 |

| AB | 1747-ACNR15 |

| AB | 1747-ACNR15/A |

| AB | 1747-ASB |

| AB | 1747-ASB/A |

| AB | 1747-ASB1747-L511 |

| AB | 1747-BA |

| AB | 1747-BSN |

| AB | 1747-BSN1771-IFE |

| AB | 1747-CP3/A |