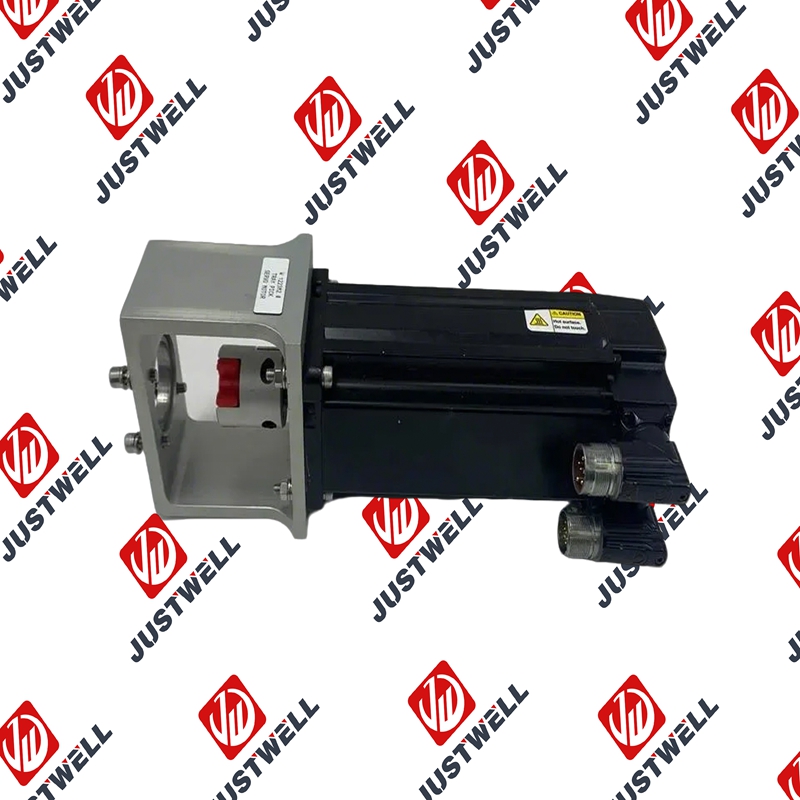

Description

2711P-RP8A Allen‑Bradley ervo motor

Product Dimensions:

Allen-Bradley Motor Products Overview

Allen-Bradley, a brand under Rockwell Automation, offers a comprehensive range of motor products designed for industrial automation. These include AC and DC motors, servo motors, and integrated motor-drive solutions. While Allen-Bradley is renowned for motor control components (e.g., drives, starters, and controllers), it also provides motors such as the MP-Series low-inertia servo motors, Kinetix servo motors, and PowerFlex-integrated motor systems. These products emphasize energy efficiency, precision control, and integration with automation systems. Below is a detailed breakdown based on key product lines.

Detailed Description

Allen-Bradley motors are engineered for demanding industrial environments, focusing on high-performance motion control. Key categories include:

- MP-Series Low-Inertia Motors: Compact, high-torque servo motors for dynamic applications. They feature low rotor inertia for rapid acceleration/deceleration and are available in 400V-class configurations. These motors support rotary motion and are UL Recognized to applicable UL and CSA standards.

- Kinetix Servo Motors (e.g., VPL Series): Linear and rotary servo motors based on MP technology, optimized for high-volume production. The VPL low-inertia variant excels in reciprocating motion, with features like high torque density and compatibility with Kinetix drives.

- PowerFlex Integrated Motors (e.g., Armor PowerFlex 35-Series and 330 Drive Motor): Pre-engineered, on-machine solutions combining ultra-efficient IE5 permanent magnet motors with variable frequency drives (VFDs). These are designed for harsh environments, offering near-motor mounting and logic integration for simplified setups.

- NEMA Premium Efficient Motors: General-purpose AC induction motors meeting NEMA standards for energy savings and reliability in continuous-duty applications.

These motors integrate seamlessly with Allen-Bradley ecosystems, including PLCs and Ethernet/IP networks, enabling intelligent motor control for predictive maintenance and optimization.

Product Parameters

Parameters vary by model, but here are representative specifications for popular lines (consult Rockwell Automation for exact configurations):

| Product Line | Voltage Range | Power Rating | Torque (Continuous/Peak) | Speed Range | Inertia | Other Key Specs |

|---|---|---|---|---|---|---|

| MP-Series Low-Inertia (MPL) | 400V AC | 0.5–22 kW | Up to 28 Nm / 84 Nm | Up to 6,000 RPM | Low rotor inertia (e.g., 0.00015–0.012 kg·m²) | Frame sizes: A–E; IP65 enclosure; M58 connectors (rotatable in 90° increments) |

| Kinetix VPL Low-Inertia | 200–400V AC | 0.1–3.7 kW | Up to 2.4 Nm / 7.2 Nm | 0–5,000 RPM | Ultra-low inertia for high acceleration | High torque density; Continuous duty cycle; UL/CSA certified |

| PowerFlex 525/330 Integrated | 100–600V AC | 0.4–22 kW (0.5–30 HP) | Varies by motor (e.g., IE5 efficiency >95%) | 0–4,000 RPM | N/A (integrated VFD) | Compact footprint; Embedded Ethernet; Ambient temp: -20°C to 50°C |

| NEMA Premium AC Induction | 230/460V AC | 0.75–500 HP | Standard NEMA torque curves | 1,200–3,600 RPM | Medium inertia | Efficiency: IE3/IE4 compliant; TEFC enclosure; Service factor: 1.15 |

These specs support global standards (NEMA, IEC) and can be sized using Rockwell’s Motion Analyzer software.

Product Advantages

Allen-Bradley motors deliver superior performance in industrial settings, with the following benefits:

- Energy Efficiency: NEMA Premium and IE5-rated motors reduce consumption by up to 20–30% compared to standard models, lowering operational costs and supporting sustainability goals (e.g., IEC 61800-9-2 compliance).

- Precision and Reliability: Low-inertia designs enable fast response times (e.g., for robotics), while robust construction handles harsh conditions (IP65 ratings, wide temperature tolerance). Integrated safety features like Safe Torque Off (SIL3/PLe) minimize downtime and enhance worker protection.

- Scalability and Integration: Seamless connectivity via Ethernet/IP and compatibility with PowerFlex drives allow easy expansion from simple to complex systems. Pre-engineered solutions like Armor series simplify installation, reducing commissioning time by up to 50%.

- Cost Savings: Predictive diagnostics and adaptive algorithms extend equipment life, while global SCCR certification ensures compliance without custom testing.

- Flexibility: Supports diverse control modes (e.g., V/Hz, vector) and mounting options for retrofits or new builds.

Precautions and Notes

To ensure safe and optimal operation:

- Installation: Use certified combinations for short-circuit protection (verified via Rockwell’s SCCR Tool). Position connectors (e.g., M58 on MP-Series) correctly to avoid misalignment; physically remove and rotate in 90° increments if needed.

- Operation: Monitor for faults like overvoltage, ground faults, or thermal derating—common in VFD-integrated systems. Avoid exceeding ambient temperature limits (typically -20°C to 50°C) to prevent overheating. Implement embedded safety options for high-risk applications.

- Maintenance: Regularly check for inrush currents in DOL starters (up to 6–8x full load), which can stress power supplies. Use soft starters for smoother acceleration. Do not modify motors without factory approval to maintain UL/CSA certification.

- General Warnings: High-voltage models require qualified personnel for handling. In explosive environments, select intrinsically safe variants. Always reference product manuals for model-specific derating and environmental precautions.

Product Applications

Allen-Bradley motors are versatile across industries:

- Manufacturing and Assembly: Kinetix VPL for high-speed reciprocating tasks like packaging lines and pick-and-place robots.

- Material Handling: PowerFlex integrated motors for conveyors, cranes, and pumps in warehouses and logistics.

- Process Industries: MP-Series for precise control in food/beverage mixing, chemical dosing, and HVAC fans.

- Energy and Utilities: NEMA Premium motors for pumps and compressors, optimizing efficiency in oil/gas and water treatment.

- Motion Control Systems: Servo motors in CNC machines, 3D printing, and automotive assembly for dynamic positioning.

For customized selections, use Rockwell Automation’s online tools or consult a distributor. Visit rockwellautomation.com for the latest catalogs and support.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| AB | 1746-OB16 |

| AB | 1746-OB16E |

| AB | 1746-OB32 |

| AB | 1746-OB32E |

| AB | 1746-OB8 |

| AB | 1746-OBP16 |

| AB | 1746-OG16 |

| AB | 1746-OV16 |

| AB | 1746-OV32 |

| AB | 1746-OW16 |

| AB | 1746-OW16/C |

| AB | 1746-OW16/C/D |

| AB | 1746-OW4 |

| AB | 1746-OW8 |

| AB | 1746-OX8 |

| AB | 1746-P1 |

| AB | 1746-P2 |

| AB | 1746-P2/C |

| AB | 1746-P3 |

| AB | 1746-P4 |

| AB | 1746-P5 |

| AB | 1746-P6 |

| AB | 1746-P7 |

| AB | 1746SC-NI8U |

| AB | 1746SC-OAP8I |

| AB | 1747-ACN15 |

| AB | 1747-ACNR15 |

| AB | 1747-ACNR15/A |

| AB | 1747-ASB |

| AB | 1747-ASB/A |

| AB | 1747-ASB1747-L511 |

| AB | 1747-BA |

| AB | 1747-BSN |

| AB | 1747-BSN1771-IFE |

| AB | 1747-CP3/A |