Description

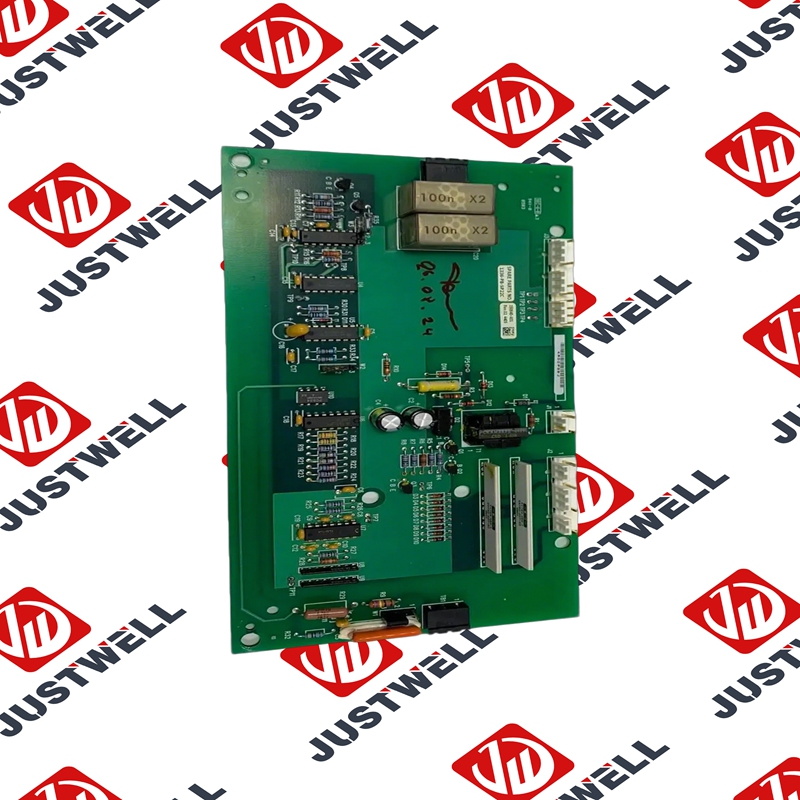

2090-SCVG50-0 Allen‑Bradley Central control module

Product Dimensions:

Allen-Bradley, a flagship brand under Rockwell Automation, does not produce traditional consumer-grade computer motherboards (e.g., for PCs). Instead, their “motherboards” refer to industrial-grade chassis or backplanes used in programmable logic controllers (PLCs) and industrial control systems. These serve as the foundational mounting and interconnection platforms for CPUs, I/O modules, power supplies, and communication adapters in rugged environments. Key product families include those in the 17xx series (e.g., 1771 for legacy PLC-5 systems) and modern chassis-based systems like ControlLogix (1756 series). Below is a detailed breakdown based on official Rockwell Automation specifications.

Product Detailed Description

Allen-Bradley chassis/backplanes are modular mounting assemblies designed for high-reliability industrial automation. They provide electrical and mechanical support for inserting control modules, enabling scalable system architectures.

- 1771 I/O Chassis (Legacy Series): Part of the PLC-5 family, these are rack-mounted backplanes for discrete and analog I/O modules. They support up to 16 slots in universal designs, with remote I/O variants for distributed setups. Constructed from steel for durability in harsh conditions.

- 1756 Chassis (ControlLogix Series): Modern, high-performance backplanes for ControlLogix/GuardLogix controllers. Available in sizes from 4 to 17 slots (e.g., 1756-A4, 1756-A10R, 1756-A17), with redundant power options. They use a high-speed local bus for module communication, supporting EtherNet/IP, ControlNet, and DeviceNet protocols.

- 1791/1732 ArmorBlock Chassis (Distributed I/O): Compact, DIN-rail mountable blocks for in-cabinet or on-machine I/O, integrating backplane functionality with sealed IP67 ratings for harsh environments.

These products emphasize modularity, allowing hot-swapping of modules without system downtime, and are certified for global standards like UL, CE, and ATEX for hazardous locations.

Product Parameters/Specifications

Parameters vary by model, but here are key specs for representative products (sourced from Rockwell Automation documentation):

| Parameter | 1771 Universal Chassis (e.g., 1771-A3) | 1756 ControlLogix Chassis (e.g., 1756-A10) | 1732 ArmorBlock Guard I/O (e.g., 1732E-8B8X12D) |

|---|---|---|---|

| Slots/Modules Supported | Up to 10 I/O modules | 10 slots (expandable to 17) | 28 points (16 inputs, 12 outputs) |

| Backplane Bus Speed | 1 Mbps (remote I/O) | 106.88 Mbps (local bus) | EtherNet/IP (CIP Safety, up to 100 Mbps) |

| Power Requirements | 24V DC, 2A max draw | Dual redundant 24V DC (1.5A per supply) | 24V DC, 0.75A max |

| Dimensions (H x W x D) | 8.5″ x 19.6″ x 4.7″ (21.6 x 49.8 x 11.9 cm) | 8.5″ x 16″ x 6″ (21.6 x 40.6 x 15.2 cm) | 6.3″ x 2″ x 5.1″ (16 x 5 x 13 cm) |

| Operating Temperature | 0–60°C (32–140°F) | -20–60°C (-4–140°F) | -20–70°C (-4–158°F) |

| Mounting | Rack/panel mount | DIN rail or panel | DIN rail, IP20/IP67 rated |

| Certifications | UL, CE, CSA | UL, CE, ATEX, SIL 3 (with Guard modules) | TÜV SIL 3, Cat. 4, PLe |

| Weight | ~5 lbs (2.3 kg) | ~4.5 lbs (2 kg) | ~1.1 lbs (0.5 kg) |

For full datasheets, refer to Rockwell’s Product Compatibility and Download Center.

Product Advantages

Allen-Bradley chassis/backplanes offer superior performance in industrial settings compared to generic PC motherboards:

- Rugged Durability: Built for extreme conditions (vibration, dust, EMI), with IP20–IP67 ratings and wide temperature ranges, reducing failure rates in factories.

- Scalability and Flexibility: Modular design supports easy expansion without rewiring; supports mixed I/O types (digital, analog, safety) and multiple protocols for future-proofing.

- High Reliability and Redundancy: Hot-swappable modules and dual power supplies ensure 99.999% uptime; integrated diagnostics via Studio 5000 software minimize troubleshooting time.

- Integrated Safety: Guard I/O variants achieve SIL 3/Cat. 4 safety levels, ideal for hazardous applications, with CIP Safety for seamless network integration.

- Cost Efficiency: Low maintenance (e.g., no soldering required) and compatibility with third-party devices reduce total ownership costs by up to 30% in distributed systems.

- Ease of Use: Point-and-click configuration in RSLogix/Studio 5000 software speeds commissioning.

Notes/Cautions

- Installation: Always ground chassis properly to avoid EMI issues; use only compatible Allen-Bradley modules to prevent bus faults. Follow ESD protection guidelines during handling.

- Environmental Limits: Avoid exceeding temperature/humidity specs; in humid areas, use conformal-coated variants to prevent corrosion.

- Compatibility: Legacy 1771 series is end-of-life in many regions—migrate to 1756 for ongoing support. Verify firmware versions for EtherNet/IP compliance.

- Safety: For Guard I/O, ensure CIP Safety is enabled; improper configuration can void certifications. Power off systems before inserting/removing modules in non-hot-swap chassis.

- Maintenance: Regularly update firmware via Rockwell’s PCDC; avoid mixing voltage levels (e.g., 5V/24V) without isolators to prevent damage.

- Warranty: Standard 18-month warranty; extended options available through Rockwell distributors.

Product Applications

Allen-Bradley chassis/backplanes are deployed in demanding industrial automation scenarios:

- Manufacturing and Assembly Lines: ControlLogix chassis for robotic welding, conveyor systems, and palletizing (e.g., automotive plants).

- Process Industries: 1771/1756 for batch processing, mixing, and packaging in food/beverage or pharmaceuticals, integrating with SCADA for real-time monitoring.

- Energy and Utilities: Distributed ArmorBlock for oil/gas pipelines, water treatment, and power distribution, handling remote I/O over EtherNet/IP.

- Safety-Critical Systems: Guard I/O chassis in mining, aerospace, and material handling for emergency stops and motion control.

- Motion and Drives: Integration with PowerFlex drives for precise servo control in printing, textiles, and CNC machines.

- Building Automation: Smaller 1791 modules for HVAC and lighting control in commercial facilities.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| AB | 1746-OB16 |

| AB | 1746-OB16E |

| AB | 1746-OB32 |

| AB | 1746-OB32E |

| AB | 1746-OB8 |

| AB | 1746-OBP16 |

| AB | 1746-OG16 |

| AB | 1746-OV16 |

| AB | 1746-OV32 |

| AB | 1746-OW16 |

| AB | 1746-OW16/C |

| AB | 1746-OW16/C/D |

| AB | 1746-OW4 |

| AB | 1746-OW8 |

| AB | 1746-OX8 |

| AB | 1746-P1 |

| AB | 1746-P2 |

| AB | 1746-P2/C |

| AB | 1746-P3 |

| AB | 1746-P4 |

| AB | 1746-P5 |

| AB | 1746-P6 |

| AB | 1746-P7 |

| AB | 1746SC-NI8U |

| AB | 1746SC-OAP8I |

| AB | 1747-ACN15 |

| AB | 1747-ACNR15 |

| AB | 1747-ACNR15/A |

| AB | 1747-ASB |

| AB | 1747-ASB/A |

| AB | 1747-ASB1747-L511 |

| AB | 1747-BA |

| AB | 1747-BSN |

| AB | 1747-BSN1771-IFE |

| AB | 1747-CP3/A |