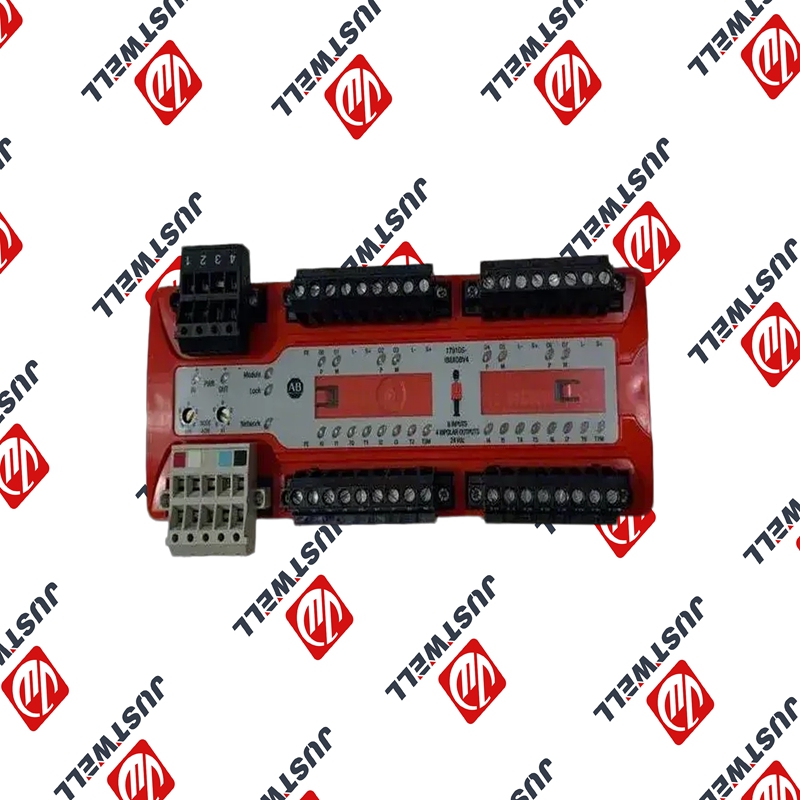

Description

193-EC3LH Allen‑Bradley Central control module

Product Dimensions:

Product Detailed Description

The Allen-Bradley a high-performance control module designed by Rockwell Automation for integration with the PowerFlex 527 series of adjustable frequency AC drives. It serves as a central control component in industrial drive systems, managing drive operations such as speed control, torque regulation, and system diagnostics. This spare part kit includes the control module and a front cover for easy installation and protection. It is engineered for reliability in demanding environments, supporting seamless replacement in existing setups. The module enables precise motor control through embedded programming capabilities and interfaces with Logix controllers for enhanced automation. As part of the PowerFlex ecosystem, it contributes to efficient, scalable industrial motion control solutions.

Product Parameters (Specifications)

The 25C-CTM1 module adheres to the following key technical specifications:

| Parameter | Value/Details |

|---|---|

| Manufacturer | Allen-Bradley (Rockwell Automation) |

| Product Line | PowerFlex 527 Series |

| UPC | 887172532153 |

| Weight | 0.75 lbs (0.34 kg) |

| Type | Replacement Control Module (includes Front Cover) |

| Compatible Frame Sizes | A to E |

| Voltage Rating | 240/480/600 VAC |

| Frequency Tolerance | 47–63 Hz |

| Voltage Tolerance | -15% to +10% |

| Efficiency Rating | 97.5% (typical) |

| Programmable Output Frequency Range | 0–590 Hz |

| Operating Ambient Temperature | -20°C to 60°C (-4°F to 140°F) |

| Storage Temperature (Frames A–D) | -40°C to 85°C (-40°F to 185°F) |

| Storage Temperature (Frame E) | -40°C to 70°C (-40°F to 158°F) |

| Relative Humidity | 0–95% (non-condensing) |

| Maximum Operating Altitude (No Derating) | 1000 m (3300 ft) |

| Maximum Operating Altitude (With Derating) | 4000 m (13,200 ft) |

| Shock Tolerance | 15 g |

| Vibration Tolerance | 2 g |

| Mounting Options | DIN rail or panel screws |

| Enclosure Rating | IP20 (Open Type) |

| Certifications | c-UL-us, RCM, CE, ATEX, KCC, EAC |

Dimensions are not explicitly detailed in product documentation but align with standard PowerFlex 527 drive chassis for frames A–E.

Product Advantages

The offers several key advantages that enhance its utility in industrial automation:

- Versatile Compatibility: Supports a wide range of frame sizes (A–E) and voltage classes (240V, 480V, 600V), allowing easy integration or replacement across diverse drive systems without major modifications.

- High Durability and Reliability: Withstands harsh conditions, including 15 g shock, 2 g vibration, and wide temperature ranges, ensuring long-term performance in rugged industrial settings.

- Energy Efficiency: Contributes to the PowerFlex 527’s 97.5% typical efficiency, reducing operational costs and supporting sustainable manufacturing practices.

- Flexible Control Options: Provides programmable frequency output up to 590 Hz, enabling precise speed and torque control for optimized motor performance.

- Ease of Installation and Maintenance: Includes a front cover for protection and supports quick mounting via DIN rail or screws; Removal and Insertion Under Power (RIUP) capability allows hot-swapping without system downtime.

- Advanced Protection Features: Built-in diagnostics and safety integrations minimize downtime and protect against faults, extending equipment lifespan.

- Seamless Integration: Tight compatibility with Rockwell’s Logix controllers and Studio 5000 software streamlines programming and monitoring.

Precautions (Attention Matters)

When handling, installing, or operating, observe the following precautions to ensure safety and optimal performance:

- Environmental Limits: Do not exceed the operating temperature range (-20°C to 60°C) or altitude (1000 m without derating); derate performance above these thresholds to avoid overheating or reduced efficiency.

- Humidity and Condensation: Maintain relative humidity below 95% and prevent condensation, as it may cause corrosion or electrical faults.

- Mechanical Stress: Avoid impacts exceeding 15 g shock or 2 g vibration during transport or operation; secure mounting firmly to prevent loosening.

- Installation Safety: Power off the drive system before installation or replacement. Use RIUP only if the system supports it and follow ESD (electrostatic discharge) precautions to protect sensitive electronics.

- Firmware Considerations: Verify firmware version compatibility with your application; Rockwell Automation does not guarantee pre-installed firmware revisions. Users must adhere to End-User License Agreements for any updates.

- Warranty and Sourcing: As a spare part, it may be sourced from third-party suppliers without original manufacturer warranty—opt for authorized distributors for full support. Inspect for damage upon receipt and test in a controlled environment before deployment.

- Compliance: Ensure installation complies with local electrical codes and certifications (e.g., CE, UL); improper use may void certifications or pose hazards.

Product Applications

The ideal for high-performance industrial applications requiring reliable AC drive control:

- Manufacturing Automation: Used in conveyor systems, pumps, and fans for precise speed regulation in assembly lines and material handling.

- Process Industries: Controls motors in mixing, pumping, and HVAC systems within food & beverage, chemical, and water treatment facilities.

- Motion Control Systems: Integrates with robotics and packaging machines for torque and position control, enhancing productivity.

- OEM Equipment: Serves as a replacement or upgrade in original equipment manufacturer (OEM) designs for compact, efficient drive solutions.

- Harsh Environments: Suitable for XT variants in extreme temperatures or dusty settings, such as mining or oil & gas operations. Its modular design and broad compatibility make it a go-to for retrofitting legacy systems or building new EtherNet/IP-enabled automation networks.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| AB | 1746-OB16 |

| AB | 1746-OB16E |

| AB | 1746-OB32 |

| AB | 1746-OB32E |

| AB | 1746-OB8 |

| AB | 1746-OBP16 |

| AB | 1746-OG16 |

| AB | 1746-OV16 |

| AB | 1746-OV32 |

| AB | 1746-OW16 |

| AB | 1746-OW16/C |

| AB | 1746-OW16/C/D |

| AB | 1746-OW4 |

| AB | 1746-OW8 |

| AB | 1746-OX8 |

| AB | 1746-P1 |

| AB | 1746-P2 |

| AB | 1746-P2/C |

| AB | 1746-P3 |

| AB | 1746-P4 |

| AB | 1746-P5 |

| AB | 1746-P6 |

| AB | 1746-P7 |

| AB | 1746SC-NI8U |

| AB | 1746SC-OAP8I |

| AB | 1747-ACN15 |

| AB | 1747-ACNR15 |

| AB | 1747-ACNR15/A |

| AB | 1747-ASB |

| AB | 1747-ASB/A |

| AB | 1747-ASB1747-L511 |

| AB | 1747-BA |

| AB | 1747-BSN |

| AB | 1747-BSN1771-IFE |

| AB | 1747-CP3/A |