Description

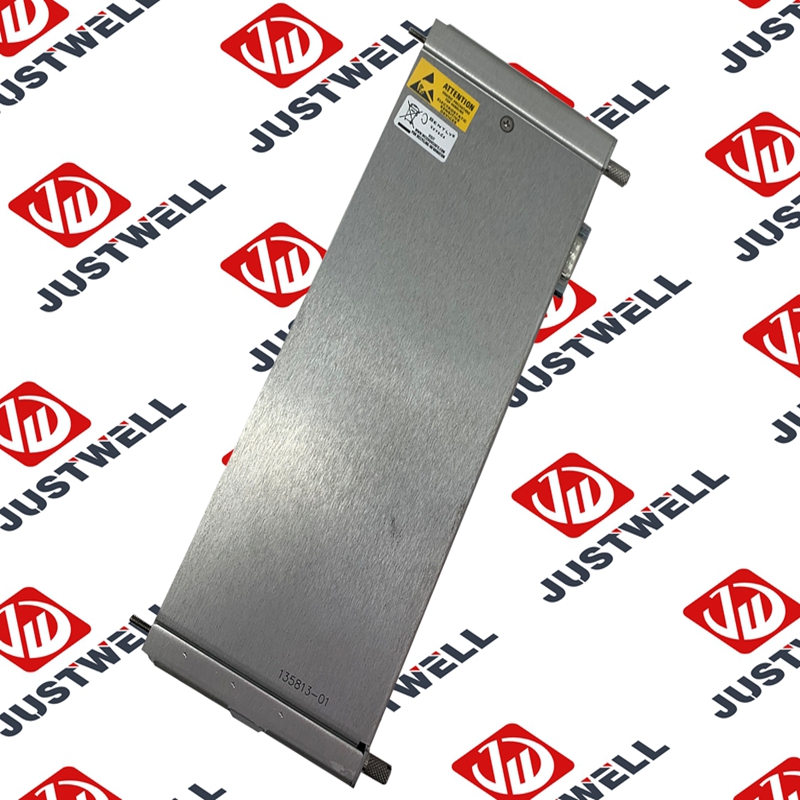

177313-A02-B02 Bently Processor module

Product Dimensions:

Product Detailed Description

The Bently Nevada 3500/15 Power Supply Module is a critical component of the Bently Nevada 3500 Series Machinery Protection System, designed for reliable power delivery in industrial condition monitoring applications. It is a half-height module that provides stable AC or DC power to the entire rack, ensuring uninterrupted operation of vibration monitoring and protection systems for rotating machinery. Available in variants such as Universal AC (e.g., part number 127610-01), High Voltage DC (e.g., 129486-01), and Low Voltage DC (e.g., 133292-01), it converts a wide range of input voltages into regulated outputs suitable for other 3500 modules. The module supports redundant configurations, enhancing system uptime in demanding environments like oil and gas, power generation, and manufacturing.

Product Parameters

| Parameter | Details |

|---|---|

| Module Type | Half-height power supply module (AC or DC variants) |

| Installation | Designated slots on the left side of the 3500 rack (lower slot primary, upper slot backup) |

| Input Voltage (Universal AC) | 90–264 VAC, 47–63 Hz |

| Input Voltage (High Voltage DC) | 88–140 VDC |

| Input Voltage (Low Voltage DC) | 20–30 VDC |

| Output Voltage | Regulated DC voltages (e.g., +24 VDC, -12 VDC) for rack components |

| Power Capacity | Capable of powering a full 3500 rack (up to 14 slots) |

| Redundancy | Supports 1 or 2 supplies (hot-swappable; no disruption during replacement if redundant) |

| Dimensions | Approximately 5.7 cm x 20.3 cm x 33.0 cm (fits standard 19-inch rack) |

| Weight | Approximately 1.1 kg |

| Operating Temperature | -30°C to +65°C (standard industrial range) |

| Efficiency | High efficiency conversion with minimal energy loss |

| Certifications | CE compliant; designed for hazardous locations (consult specific variant) |

Product Advantages

- Redundant Power Configuration: Allows dual supplies (AC/DC mix) for failover protection, minimizing downtime and preventing unexpected shutdowns in critical operations.

- Hot-Swappable Design: Modules can be removed or inserted without interrupting rack operation, enabling quick maintenance and reducing repair time.

- Wide Input Voltage Tolerance: Accepts broad AC/DC ranges, making it adaptable to varying industrial power conditions without additional converters.

- High Reliability and Efficiency: Provides stable, low-noise power output, extending the lifespan of connected monitoring equipment and reducing overall system failures.

- Seamless Integration: Fully compatible with the Bently Nevada 3500 ecosystem, including Proximitor® sensors, for plug-and-play deployment in machinery protection setups.

- Cost-Effective Maintenance: Interchangeable components (probe, cable, sensor) eliminate need for recalibration, saving time and costs in large-scale installations.

Precautions (Notes)

- Installation Restrictions: Must be installed only in the designated left-side rack slots; improper placement may cause power instability or system faults.

- Redundancy Requirement: For mission-critical applications, always use dual supplies to avoid single-point failures; single-supply setups increase risk of total rack shutdown.

- Voltage Compatibility: Verify input voltage matches the variant (e.g., do not use Low Voltage DC module on high-voltage lines) to prevent damage or fire hazards.

- Environmental Limits: Operate within -30°C to +65°C and avoid exposure to excessive dust, moisture, or corrosive substances; use in hazardous areas requires certified enclosures.

- Maintenance: Hot-swap only when redundant power is active; always power down the rack for non-redundant changes. Consult Bently Nevada documentation for firmware updates.

- Safety: Ground the system properly and follow ESD precautions during handling to avoid electrostatic damage to sensitive electronics.

Product Applications

- Rotating Machinery Protection: Powers vibration monitoring systems in gas turbines, steam turbines, generators, and compressors in power plants and hydroelectric facilities.

- Oil and Gas Industry: Supports condition monitoring for pumps, fans, and motors in upstream/downstream operations, enabling predictive maintenance to prevent costly outages.

- Manufacturing and Process Plants: Used in petrochemical refineries, mining equipment, and pulp/paper mills for real-time machinery health surveillance.

- Hydroelectric and Utility Networks: Integrates with Bently Nevada systems to monitor axial displacement and radial vibration in large-scale turbines and pumps.

- Aerospace and Marine Propulsion: Applies to high-speed rotating assets requiring continuous protection against transients and noise-driven trips.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| BENTLY NEVADA | 3300XL 8MM |

| BENTLY NEVADA | 330101-00-18-10-02-05 |

| BENTLY NEVADA | 330101-00-28-10-02-05 |

| BENTLY NEVADA | 330103-00-03-10-02-05 |

| BENTLY NEVADA | 330103-00-04-10-02-05 |

| BENTLY NEVADA | 330103-00-05-05-02-05 |

| BENTLY NEVADA | 330103-00-05-10-02-05 |

| BENTLY NEVADA | 330103-00-14-10-01-00 |

| BENTLY NEVADA | 330103-00-18-05-02-05 |

| BENTLY NEVADA | 330103-05-10-10-02-05 |

| BENTLY NEVADA | 330103-10-14-10-02-05 |

| BENTLY NEVADA | 330104-00-04-10-02-05 |

| BENTLY NEVADA | 330104-00-06-10-11-00 |

| BENTLY NEVADA | 330104-00-11-10-02-05 |

| BENTLY NEVADA | 330104-05-13-10-02-00 |

| BENTLY NEVADA | 330104-13-20-10-02-00 |

| BENTLY NEVADA | 330104-15-23-10-02-00 |

| BENTLY NEVADA | 330104-19-25-10-11-05 |

| BENTLY NEVADA | 330105-02-12-90-02-05 |

| BENTLY NEVADA | 330130-040-02-05 |

| BENTLY NEVADA | 330130-045-02-05 |

| BENTLY NEVADA | 330173-00-18-10-02-05 |

| BENTLY NEVADA | 330703-000-040-10-11-00 |

| BENTLY NEVADA | 330730-080-02-00 |

| BENTLY NEVADA | 330780-91-00 |

| BENTLY NEVADA | 330930-040-01-00 |

| BENTLY NEVADA | 33104-00-10-10-02-05 |

| BENTLY NEVADA | 3500/05 3500/05-01-02-00-00-01 |

| BENTLY NEVADA | 3500/15 127610-01 |

| BENTLY NEVADA | 3500/22M 138607-01 |