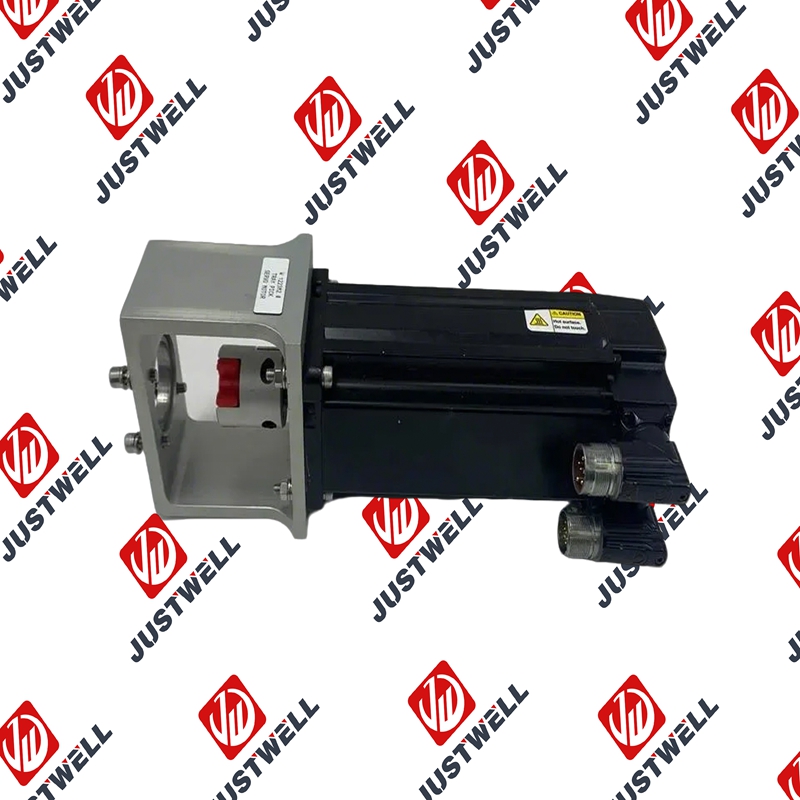

Description

150-F43NBDD Allen‑Bradley motor

Product Dimensions:

Allen-Bradley, a brand under Rockwell Automation, offers a comprehensive range of industrial motors designed for robust performance in demanding automation environments. Their motor portfolio includes AC induction motors, DC motors, servo motors, linear motors, and electric cylinders, optimized for integration with drives, controllers, and PLC systems. These products emphasize efficiency, durability, and seamless connectivity, supporting applications from basic speed control to high-precision motion tasks. Below is a structured breakdown of key aspects.

Product Detailed Description

Allen-Bradley motors are engineered for industrial reliability and versatility, featuring advanced designs that reduce noise, extend component life, and enable precise control. Key product lines include:

- PowerFlex AC Motors: General-purpose AC induction motors with NEMA premium efficiency ratings, available in totally enclosed fan-cooled (TEFC), totally enclosed non-ventilated (TENV), and blower-cooled configurations. They support open or closed-loop PWM drive control and are built with rugged rolled steel or cast iron frames.

- Kinetix Servo Motors: High-performance rotary servo motors (e.g., MP-Series, VP-Series, VPL low-inertia models) for dynamic motion applications. These leverage Logix platform integration for scalable servo control, offering options for continuous or high-torque duty cycles.

- DC Motors (Bulletin 1326/1326AB Series): Compact DC servo motors with state-of-the-art brush technology, including cartridge brush designs that extend brush life up to four times industry standards. Suitable for precise speed/torque regulation.

- Linear Motors (LDC-Series): Iron-core direct-drive linear motors that connect directly to payloads for fast settling times and high force density, eliminating backlash in linear motion systems.

- Electric Cylinders (MPAR MP-Series, TLAR TL-Series): Compact, rod-style actuators providing linear motion with dynamic response, ideal for replacing pneumatic or hydraulic systems.

These motors are inverter-grade, with low acoustical and electrical noise, and conform to NEMA Design B characteristics for smooth operation.

Product Parameters/Specifications

Allen-Bradley motors are available in a wide range of sizes and ratings to match diverse industrial needs. Common specifications across lines include:

| Parameter | Typical Range/Specs |

|---|---|

| Power Rating | 0.5–1400 HP (0.37–1044 kW) for AC/DC; up to 5000 W for servo motors |

| Voltage | 200–690V AC input; 24–460V for servo/DC models |

| Speed/Torque | Up to 6000 RPM; constant torque to zero speed; peak torque 200–300% of continuous |

| Efficiency | NEMA Premium (IE3/IE4 equivalent); up to 95% for servo models |

| Enclosure Types | TEFC, TENV, IP65/IP67-rated for harsh environments |

| Frame Sizes | NEMA 00–9; metric equivalents for global standards |

| Cooling | Fan-cooled, blower-cooled, or self-ventilated |

| Inertia Options | Low-inertia (VPL series) for rapid acceleration; high-torque for heavy loads |

| Communication | EtherNet/IP, DeviceNet, SERCOS for integrated control |

| Mounting | Foot, flange, or direct-drive; customizable shafts and brakes |

Specific models like the SMC-2 controllers (often paired with motors) handle 150–480A currents for 3-phase motors at 200–460V AC. Always refer to product datasheets for exact model variants.

Product Advantages

Allen-Bradley motors stand out for their integration, longevity, and efficiency in industrial settings:

- High Efficiency and Energy Savings: NEMA premium designs reduce energy consumption by up to 20% compared to standard motors, with features like predictive diagnostics to minimize downtime and optimize performance.

- Durability and Reliability: Rugged construction withstands harsh environments (e.g., vibration, dust, moisture), with extended brush life in DC models and inverter-grade insulation for PWM compatibility.

- Seamless Integration: Native support for Rockwell’s Logix ecosystem, including EtherNet/IP for real-time connectivity, enabling scalable systems from single-axis to multi-axis control.

- Precision and Flexibility: Low-inertia options for high-speed reciprocating motion; direct-drive linear designs eliminate mechanical wear, improving settling times and accuracy.

- Cost-Effectiveness: Reduced maintenance needs (e.g., easy brush inspection) and compatibility with retrofits lower total ownership costs, while safety features like integrated braking enhance operator protection.

These advantages contribute to increased productivity, with users reporting up to 30% faster development times via RSLogix tools.

Precautions/Notes

To ensure safe and optimal operation of Allen-Bradley motors:

- Installation: Follow NEMA/IEC standards for mounting and alignment to prevent vibration-induced failures. Use proper grounding and shielding for EMI-sensitive environments.

- Environmental Limits: Operate within specified temperature ranges (-20°C to 40°C standard; derate for extremes). Avoid exposure to corrosive chemicals unless IP-rated enclosures are used.

- Maintenance: Regularly inspect brushes (in DC models) and cooling fans; schedule predictive diagnostics via connected drives to catch faults early. Do not exceed voltage/speed ratings to avoid insulation breakdown.

- Safety: Integrate with motor controllers (e.g., SMC-2) for overload/short-circuit protection. Disconnect power before servicing, and use lockout/tagout procedures.

- Compatibility: Pair with Allen-Bradley drives (e.g., PowerFlex) for best performance; mismatched setups may void warranties or reduce efficiency.

Consult Rockwell Automation’s installation manuals for model-specific guidelines.

Product Applications

Allen-Bradley motors excel in automation-heavy industries requiring reliable motion control:

- Manufacturing and Assembly: Servo and linear motors for pick-and-place robotics, conveyor systems, and high-volume production lines.

- Material Handling: AC induction motors in cranes, hoists, and sorting systems for efficient load movement.

- Packaging and Food/Beverage: Washdown-rated models for hygienic environments, with precise speed control for filling and labeling machines.

- Process Industries: DC and electric cylinders in pumps, fans, and mixers for chemical/pharmaceutical processing.

- Machine Tools and OEMs: Kinetix series for CNC machines and custom automation, supporting high-torque startup in metalworking.

These applications benefit from the motors’ scalability, making them ideal for both standalone and integrated FactoryTalk systems. For tailored selections, Rockwell’s online configurators are recommended.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| AB | 1746-OB16 |

| AB | 1746-OB16E |

| AB | 1746-OB32 |

| AB | 1746-OB32E |

| AB | 1746-OB8 |

| AB | 1746-OBP16 |

| AB | 1746-OG16 |

| AB | 1746-OV16 |

| AB | 1746-OV32 |

| AB | 1746-OW16 |

| AB | 1746-OW16/C |

| AB | 1746-OW16/C/D |

| AB | 1746-OW4 |

| AB | 1746-OW8 |

| AB | 1746-OX8 |

| AB | 1746-P1 |

| AB | 1746-P2 |

| AB | 1746-P2/C |

| AB | 1746-P3 |

| AB | 1746-P4 |

| AB | 1746-P5 |

| AB | 1746-P6 |

| AB | 1746-P7 |

| AB | 1746SC-NI8U |

| AB | 1746SC-OAP8I |

| AB | 1747-ACN15 |

| AB | 1747-ACNR15 |

| AB | 1747-ACNR15/A |

| AB | 1747-ASB |

| AB | 1747-ASB/A |

| AB | 1747-ASB1747-L511 |

| AB | 1747-BA |

| AB | 1747-BSN |

| AB | 1747-BSN1771-IFE |

| AB | 1747-CP3/A |