Description

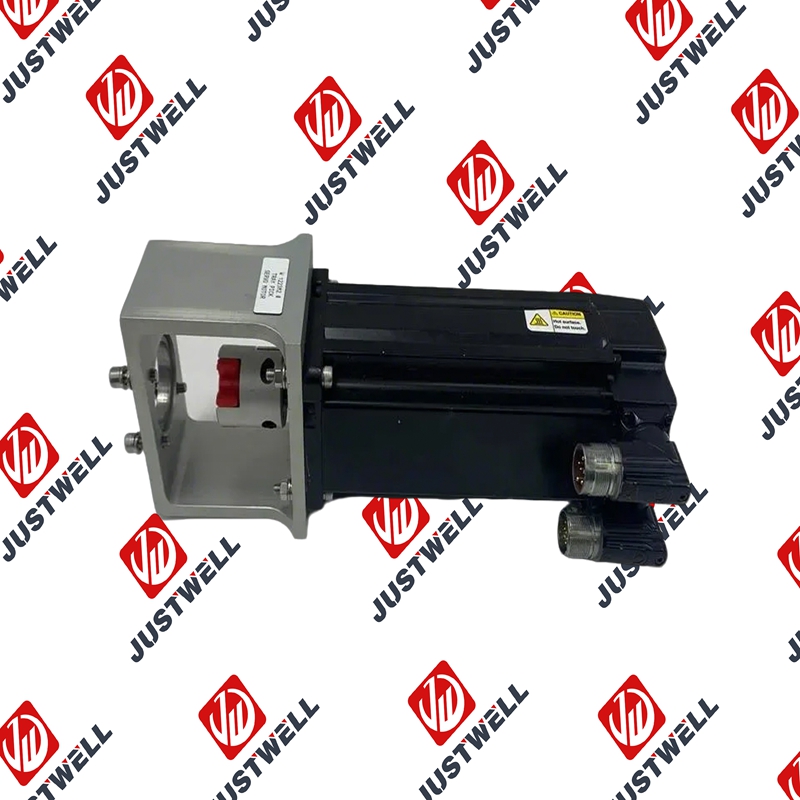

150-C317NBD Allen‑Bradley motor

Product Dimensions:

Allen-Bradley, a brand under Rockwell Automation, offers a comprehensive portfolio of industrial motors designed for demanding automation and motion control applications. These motors integrate seamlessly with Allen-Bradley drives, controllers, and software to deliver reliable, high-performance solutions. The product lineup includes AC induction motors, DC motors, servo motors, and linear motors, spanning low- to medium-voltage ranges and conforming to NEMA and IEC standards. Key series include:

- PowerFlex AC Motors: General-purpose induction motors for variable speed applications, available in NEMA premium efficiency designs with rugged rolled steel or cast iron construction.

- Bulletin 1325R DC Motors: Compact DC motors optimized for PWM drive control, featuring advanced brush technology for extended life.

- Kinetix Servo Motors (e.g., MP-Series, VP-Series, VPL/VPF/VPH): High-performance brushless servo motors for precise motion, including low-inertia options for rapid acceleration and continuous-duty models with interior permanent magnet (IPM) technology.

- Linear Motors (e.g., LDL and LDC Series): Direct-drive linear motors for high-force, non-contact motion in applications requiring exceptional responsiveness.

- Electric Cylinders (e.g., MPAR and TLAR Series): Integrated linear actuators combining motors with mechanical conversion for precise linear motion.

These motors support open- or closed-loop control, with options for totally enclosed fan-cooled (TEFC), TENV, or blower-cooled designs to handle constant torque from base speed to zero.

Product Parameters

Allen-Bradley motors are engineered with scalable specifications to match diverse industrial needs. Below is a summary of key parameters for major series (specific values vary by model; consult Rockwell Automation for exact configurations):

| Series | Voltage Range | Power/Torque Rating | Speed Range | Efficiency | Mounting/Protection | Other Specs |

|---|---|---|---|---|---|---|

| PowerFlex AC Induction | 200–690V AC | 1–1400 Hp (0.75–1044 kW) | Up to 3600 RPM | NEMA Premium (IE3 equivalent) | NEMA/IEC frames; IP55/IP66 | Inverter-grade insulation; low noise/vibration |

| Bulletin 1325R DC | Up to 500V DC | 0.25–5 Hp | 1000–3600 RPM | N/A (DC efficiency ~85–90%) | Rolled steel/cast iron; TEFC/TENV | Brush life extension (4x standard); cartridge brushes |

| Kinetix MP-Series (Medium Inertia) | 200–460V AC | Continuous torque: 0.6–148 Nm; Peak: 1.8–444 Nm | Up to 6000 RPM | Up to 95% | IEC metric; rotatable DIN connectors; IP65/IP67 | Food-grade options; hygienic washdown |

| Kinetix VP-Series (Low Inertia) | 200–460V AC | Continuous torque: 0.29–11.9 Nm; Peak: 0.88–35.7 Nm | Up to 10000 RPM | Up to 93% | Compact; EtherNet/IP feedback | Optimized for high reciprocating motion; stainless steel shafts |

| LDL/LDC Linear Motors | Up to 640V AC | Force: 178–4450 N (continuous); Peak up to 3x | Velocity: Up to 10 m/s | N/A | Iron-core/non-contact; direct payload mount | High force density; thermal management |

| MPAR/TLAR Electric Cylinders | 200–460V AC | Force: Up to 178 kN | Speed: Up to 1 m/s | Up to 90% | Integrated ball/roller screw; IP65 | Stroke lengths: 50–2000 mm; dynamic response |

Parameters are optimized for compatibility with Kinetix 5500/5700/6000/6200 drives and support protocols like EtherNet/IP for real-time feedback.

Product Advantages

Allen-Bradley motors stand out for their integration, durability, and performance in industrial environments:

- High Efficiency and Energy Savings: NEMA premium designs reduce energy consumption by up to 10% compared to standard motors, with IPM technology in VP-Series enabling continuous duty at higher torque without overheating.

- Rugged Construction: Features like inverter-grade insulation protect against electrical noise and harmonics, while cartridge brushes in DC models extend maintenance intervals by 4x. Options for washdown (IP66/IP67) and stainless steel components suit harsh conditions in food/beverage or chemical processing.

- Precision and Scalability: Low-inertia servo motors (e.g., VPL) deliver rapid acceleration/deceleration for high-throughput applications, while linear motors provide sub-micron accuracy without backlash.

- Seamless Integration: Native EtherNet/IP connectivity enables predictive diagnostics, reducing downtime by alerting on anomalies like thermal overloads. Compatibility with Logix controllers supports scalable systems from simple starters to complex motion networks.

- Cost-Effectiveness: Predictive features and modular designs lower total ownership costs through easier installation, fewer failures, and global standards compliance (UL/IEC), minimizing certification efforts.

Precautions and Notes

Proper handling and operation are critical to ensure safety and longevity:

- Installation: Use certified technicians for mounting to avoid misalignment, which can cause vibration or premature wear. Ensure proper grounding and cable routing to prevent electrical hazards; follow IEC/NEMA torque specs for connectors.

- Environmental: Avoid exceeding rated ambient temperatures (typically 0–40°C; derate above 40°C). For washdown models, use compatible cleaners to prevent corrosion. DC motors require periodic brush inspection/replacement.

- Operation: Monitor for overloads using integrated relays; do not exceed voltage/speed limits to avoid insulation breakdown. Implement safety interlocks for high-force linear motors to prevent pinch hazards.

- Maintenance: Perform regular thermal scans and diagnostic checks via FactoryTalk software. In explosive atmospheres, select ATEX/IECEx-rated variants. Always disconnect power before servicing, and adhere to lockout/tagout procedures.

- Compatibility: Pair with matched drives (e.g., Kinetix) for optimal performance; mismatched setups can lead to instability or faults like overvoltage.

Product Applications

Allen-Bradley motors power a wide array of industries requiring reliable motion control:

- Manufacturing and Assembly: Kinetix servo and linear motors for precise positioning in robotics, pick-and-place, and CNC machines.

- Food & Beverage/Pharmaceutical: Hygienic VP-Series and washdown AC motors for conveyors, fillers, and packaging lines, ensuring compliance with FDA standards.

- Material Handling: PowerFlex induction motors for pumps, fans, and hoists in warehousing and logistics.

- Energy/Oil & Gas: Rugged DC and medium-voltage motors for pumps and compressors in harsh environments.

- Automotive/Aerospace: High-torque servo motors for testing rigs and assembly automation.

- Water/Wastewater: Efficient AC motors for variable-speed pumping to optimize flow and reduce energy use.

For custom configurations or detailed datasheets, visit Rockwell Automation’s official resources or consult a distributor.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| AB | 1746-OB16 |

| AB | 1746-OB16E |

| AB | 1746-OB32 |

| AB | 1746-OB32E |

| AB | 1746-OB8 |

| AB | 1746-OBP16 |

| AB | 1746-OG16 |

| AB | 1746-OV16 |

| AB | 1746-OV32 |

| AB | 1746-OW16 |

| AB | 1746-OW16/C |

| AB | 1746-OW16/C/D |

| AB | 1746-OW4 |

| AB | 1746-OW8 |

| AB | 1746-OX8 |

| AB | 1746-P1 |

| AB | 1746-P2 |

| AB | 1746-P2/C |

| AB | 1746-P3 |

| AB | 1746-P4 |

| AB | 1746-P5 |

| AB | 1746-P6 |

| AB | 1746-P7 |

| AB | 1746SC-NI8U |

| AB | 1746SC-OAP8I |

| AB | 1747-ACN15 |

| AB | 1747-ACNR15 |

| AB | 1747-ACNR15/A |

| AB | 1747-ASB |

| AB | 1747-ASB/A |

| AB | 1747-ASB1747-L511 |

| AB | 1747-BA |

| AB | 1747-BSN |

| AB | 1747-BSN1771-IFE |

| AB | 1747-CP3/A |