● ABB’s next-generation ProcessMaster electromagnetic flowmeter enables high-speed data transmission in explosion-proof hazardous areas.

● Ethernet-APL-enabled sensors are revolutionizing the chemical, oil and gas, power, and water industries by providing fast and secure data access on top of accurate measurement.

● ABB continues to expand its portfolio of instruments supporting Ethernet-APL connectivity, facilitating broader digital acquisition and analysis of process data.

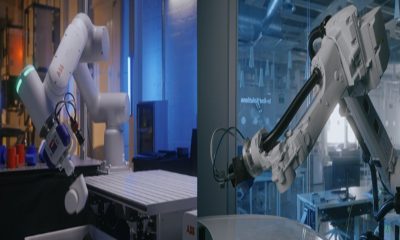

ABB has released its next-generation ProcessMaster electromagnetic flowmeter with Ethernet-APL connectivity, enabling high-speed data transmission in the field. By expanding its portfolio of instruments supporting Ethernet-APL, ABB continues to bring the advantages of Ethernet communication to industrial operations.

The new ProcessMaster flowmeter provides simplified connectivity solutions for chemical plants, oil and gas plants, and power plants, as well as the ability to acquire and analyze massive amounts of process and diagnostic data at high speed. Equipped with Ethernet-APL technology, the ProcessMaster electromagnetic flowmeter measures flow in any process application, providing efficient support for production processes and a powerful tool for the daily work of field engineers and plant managers. These new features support real-time data-driven decision-making and predictive maintenance, significantly reducing errors and downtime. Ethernet is the most common communication technology in industrial applications. However, its application remains very limited in most process industries due to concerns about security, cost, and cable length restrictions, making it difficult to establish communication networks in large industrial facilities. These problems have been solved with the introduction of Ethernet-APL technology—developed collaboratively by 12 major process automation suppliers, including ABB, and four international standards organizations.

Krishna Prashanth, Global Product Line Manager for Electromagnetic Flowmeters at ABB’s Measurement and Analysis Business Unit, stated, “Following the successful launch of our Ethernet-APL-enabled vortex and swirl flowmeters, which have been well-received in the chemical and oil and gas industries, we are bringing more devices supporting this connectivity to market. This is good news for our customers—it enables a significant leap in electromagnetic flowmeter measurement performance, even in hazardous explosion-proof areas, through high-speed data transmission in the field.”

Ethernet-APL offers enhanced data rates up to 10 Mbps, employs shielded twisted-pair cabling for secure power and data transmission within the same cable, and supports cable distances up to 1000 meters. This technology also fully integrates intrinsically safe explosion-proof features, eliminating the risk of sparks by limiting supply voltage and current, enabling Ethernet-APL deployment in hazardous environments.

By providing a high-speed channel for process data, as well as configuration and diagnostic information, Ethernet-APL offers an easily scalable solution for connecting field devices to control systems. It not only simplifies networking with all instruments in the plant but also creates new opportunities for process optimization by unlocking valuable data previously dormant in the field due to traditional bus or bandwidth bottlenecks. This series of devices integrates a web server and supports multiple communication protocols such as Profinet and Modbus TCP.

Leveraging its cybersecurity expertise and the latest internal Network Security Requirements (MCSR) standards developed for all Ethernet-APL devices, ABB ensures built-in protection for data and systems, helping customers achieve secure, real-time operation.