The ISO 10218 series of standards, developed by the International Organization for Standardization (ISO), is the core specification for industrial robot safety. It serves as the global “mother standard” for industrial robot safety and serves as the blueprint for industrial robots exported to the EU, North America, and Japan. The standard is divided into two parts: ISO 10218-1 focuses on the robot itself (design and manufacturing), while ISO 10218-2 focuses on robot integration (installation and production lines). The new revised version, released in February 2025, marks the first major revision of the series since its original release in 2011. It aims to adapt to developments and advancements in robotics technology, such as human-robot collaboration (HRC), mobile platforms, and networked systems, while also clarifying requirements to enhance compliance and safety.

Major Changes Between the 2011 and 2025 Versions

The most noticeable change between the two versions is the number of pages: ISO 10218-1 has increased from 50 to 95 pages, while ISO 10218-2 has increased from 72 to 223 pages! The new version integrates the content of the collaborative robot safety specification ISO/TS 15066:2016 to fully reflect the safety specifications for traditional industrial robot applications and collaborative applications. At the same time, in order to adapt to the changes in the new EU Machinery Regulation (effective in 2027), the new version of the standard emphasizes the standardization of functional safety, network information security and collaborative applications.

Robot Definition and Classification Expansion

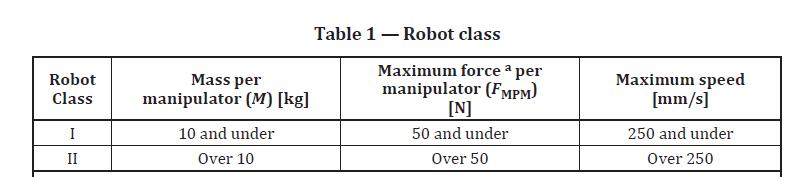

The new version introduces two robot classes: Class 1 (for robots with low payloads, designed for reasonably foreseeable misuse) and Class 2 (for robots with larger payloads). The classification criteria for Class I and Class II robots are briefly summarized in the table below. Note that a robot that fails to meet any of the Class I criteria will be classified as a Class II robot.

As can be clearly seen from the table above, Class I robots have significant limitations in terms of maximum payload, force, and speed. Consequently, the safety requirements for the two robot classes in the standard differ. For example, in terms of functional safety, Class I robots only require a minimum PL b or SIL 1.

Functional safety requirements are clearer and more flexible.

In the previous version of the standard, many safety functions were uniformly required to meet Category 3, PLd performance level. The new version explicitly defines safety functions (such as power and force limiting (PFL), speed and separation monitoring (SSM), and standstill monitoring) and allows for application-specific PL values based on risk assessment (using a risk parameter table to assess severity, exposure, probability, and avoidability, adhering to the ALARP principle). Furthermore, the new version incorporates the collaboration guidance from ISO/TS 15066, providing a comprehensive specification foundation, including hand guidance modes, crash testing, and risk assessment requirements. It also defines collaboration modes (such as PFL, SSM, and manual guidance), including biomechanical limit thresholds and verification protocols, to reduce ambiguity.

Additional Network and Communication Security

The previous version of the standard did not address network and communication security. In response to EU cybersecurity regulations, the new version adds requirements for industrial networks, including a secure communication layer and network category guidance, recognizing cybersecurity as part of functional safety.

Enhanced Risk Assessment and Validation

Guidance during the integration phase is strengthened, including specific process risks (such as hazards arising from welding). Comprehensive validation (such as simulation testing) and maintenance documentation are required, covering commissioning through dismantling.

Regarding the currently popular humanoid robot, while the new standard includes robots fixed to mobile platforms (such as hybrid robots on AGVs), it does not cover the risks associated with robot mobility. Therefore, risks associated with the movement of similar humanoid robots still need to be addressed by other standards (such as ISO 3691-4).

Action List

1. Design Department: Include the Classification Table in the project approval document. The sooner you calculate costs, the more savings you’ll have.

2. Certification Department: The 2025 certification template has been updated. Old reports will expire in 2027. Schedule a replacement in advance.

3. Procurement Department: Pay attention to the prices of products like cybersecurity chips and encryption firmware.

4. Sales Department: Include “Designed to the 2025 Standard” in your proposals so European customers can easily identify your product.

Pilz is an expert in robotics safety applications, offering proven solutions. These solutions include not only hardware products such as safety sensors and safety controllers, but also professional services like risk assessment and crash testing. With a precise understanding of the standards, we help customers achieve safe robotics applications.